La sfida: collegare in modo sicuro OT e Cloud

Per questo produttore Fortune 100, la posta in gioco era alta. Ogni stabilimento consuma ogni anno milioni di dollari di energia e acqua, e anche piccoli cali di prestazioni delle apparecchiature possono far lievitare i costi. I guasti non programmati erano ancora più gravi, perché ogni ora di fermo significava perdita di fatturato e interruzione della catena di fornitura.

I leader hanno visto una soluzione chiara: portare i dati di fabbrica in potenti piattaforme analitiche cloud di terze parti. Grazie alle informazioni in tempo reale, i team di manutenzione potevano prevedere i guasti prima che si verificassero, dare priorità alle riparazioni critiche e ottimizzare l'uso delle risorse in tutte le strutture.

Ma quello che sembrava un semplice piano di trasformazione digitale si è rapidamente imbattuto in ostacoli. I team di sicurezza informatica dell'azienda hanno sollevato preoccupazioni urgenti. Collegare i sistemi OT legacy direttamente a Internet li avrebbe esposti a una serie di rischi informatici. Molti di questi dispositivi non disponevano di moderne funzioni di sicurezza o della possibilità di essere patchati, il che li rendeva particolarmente vulnerabili. Un singolo feed di dati esposto potrebbe creare un pericoloso punto di ingresso per ransomware o attaccanti sponsorizzati dallo Stato.

Allo stesso tempo, non era possibile modificare o sostituire i sistemi di produzione per adattarli alla moderna connettività. I rischi di tempi di inattività e di superamento dei costi erano troppo elevati. L'azienda aveva bisogno di un modo per aprire le porte al cloud, ma senza compromettere l'integrità delle reti di produzione.

Avevamo bisogno di un modo per portare i dati di fabbrica in tempo reale nel cloud senza esporre i nostri sistemi di produzione a rischi informatici. OPSWAT ci ha dato questo equilibrio di visibilità e sicurezza.

Direttore della OT Security

Optical Diode MetaDefender (Fend) con integrazione Cloud

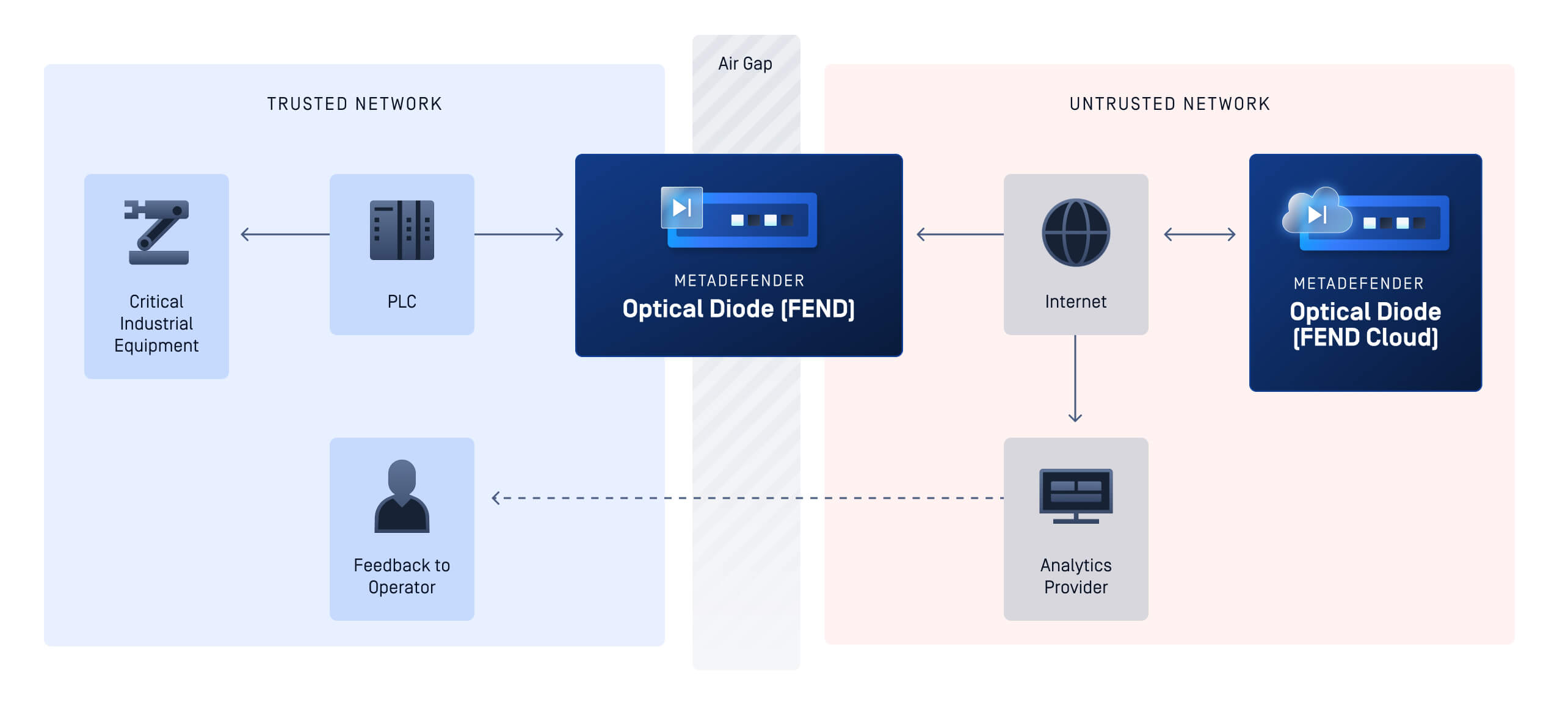

Il produttore ha utilizzato MetaDefender Optical Diodeuna piattaforma di ingestione sicura basata su AWS.

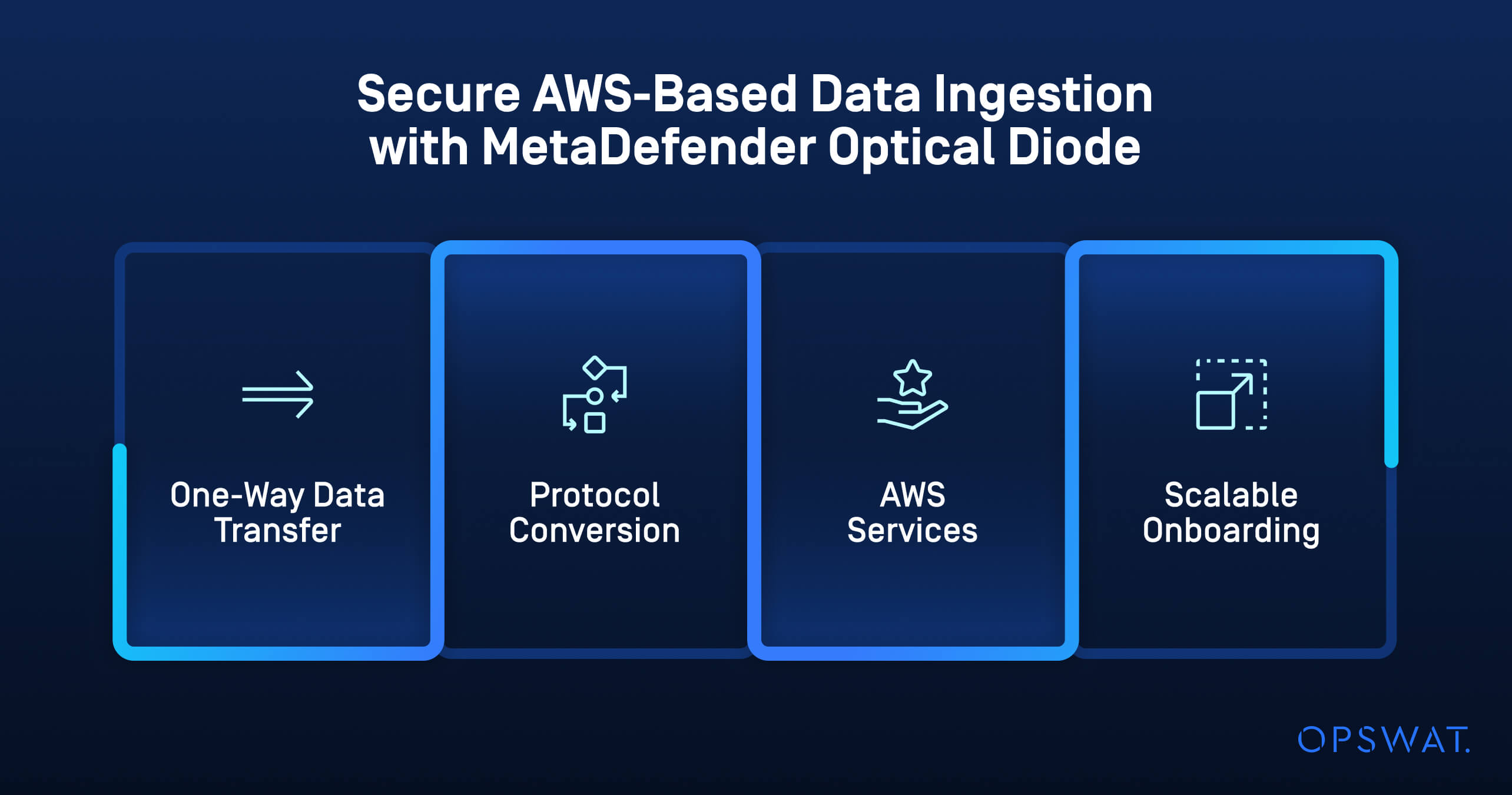

L'architettura combina la protezione fisica con i moderni servizi cloud:

- Trasferimento dei dati unidirezionale: L'isolamento ottico garantisce che i dati escano solo dall'ambiente OT. Malware, ransomware e avversari non possono entrare.

- Conversione di protocollo: I protocolli legacy (ad esempio, Modbus) vengono trasformati in formati moderni come MQTT per una perfetta integrazione nel cloud.

- Servizi AWS: I dati confluiscono nei servizi AWS IoT per l'ingestione, l'hosting e l'accesso API , mentre AWS IoT Device Defender monitora la salute e la connettività dei dispositivi.

- Onboarding scalabile: Fend Cloud consente un onboarding rapido e coerente dei dispositivi IIoT legacy in più siti.

Con ilOptical Diode MetaDefender , possiamo attingere agli analytics di AWS senza cambiare o sostituire le apparecchiature OT tradizionali, risparmiando tempo, costi e rischi.

Vicepresidente delle operazioni

Risultato: Approfondimenti in tempo reale senza compromettere la sicurezza

Con MetaDefender Optical Diode (Fend), il produttore ha ottenuto:

- Isolamento completo Cloud : La comunicazione unidirezionale Hardware garantisce che nessuna minaccia esterna possa penetrare nelle reti di produzione.

- Approfondimenti operativi in tempo reale: I dati della fabbrica fluiscono in modo sicuro verso le piattaforme di analisi AWS, supportando un processo decisionale più rapido e la manutenzione predittiva.

- Tempo di attività preservato: I dispositivi OT legacy rimangono intatti, eliminando costose sostituzioni o aggiornamenti rischiosi.

- Una più solida posizione di cybersecurity: La soluzione elimina i vettori di attacco comuni agli approcci basati sul solo software o sulla connessione diretta.

- Allineamento con le linee guida federali: L'implementazione segue le best practice delineate da CISA, NIST SP 800-82r3 e DoD UFC 4-010-06.

Hardware trasferimento unidirezionale dei datiHardware, ci ha dato la certezza che le minacce non potessero rientrare nel nostro ambiente OT, mentre i nostri team ottenevano le informazioni di cui avevano bisogno.

Responsabile della sicurezza informatica

Guardare al futuro

Questo progetto dimostra che i produttori possono portare in sicurezza la potenza del cloud ai sistemi legacy senza aprire la porta alle minacce informatiche. Con ilOptical Diode MetaDefender (Fend) OPSWAT e l'integrazione con AWS, gli operatori di infrastrutture critiche ottengono le informazioni di cui hanno bisogno mantenendo le operazioni resilienti, conformi e sicure.

Siete pronti ad esplorare soluzioni di cybersecurity su misura e leader del settore per i vostri ambienti IT/OT?